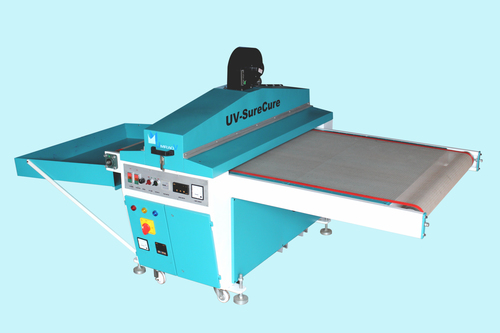

UV IR Combo Curing Unit

Price 390000.00 INR/ Unit

UV IR Combo Curing Unit Specification

- Type

- Curing Machine

- Capacity

- 45 meter/minute Kg/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Ink Type

- UV Curing Ink

- Color Management

- Other

- Control System

- PLC Control

- Power

- 440 VAC Siemens Volt (S )

- Size

- 16

- Width

- 16 Inch (in)

- Dimension (L*W*H)

- 110 x 38 x 57 Inch (in)

- Warranty

- One Year

UV IR Combo Curing Unit Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 3 Units Per Month

- Delivery Time

- 4 Week

- Packaging Details

- As per customers requirement

- Main Domestic Market

- Manipur, Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Nagaland, Uttarakhand, Daman and Diu, Lakshadweep, All India, South India, Sikkim, East India, Jharkhand, Goa, Bihar, Madhya Pradesh, Telangana, Arunachal Pradesh, Rajasthan, Assam, Delhi, Jammu and Kashmir, West India, Meghalaya, Tamil Nadu, West Bengal, Maharashtra, Mizoram, Tripura, Haryana, Gujarat, Karnataka, North India, Punjab, Uttar Pradesh, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh

About UV IR Combo Curing Unit

UV IR Combo Curing Unit 16" 300 Watts

Umrao Automation Pvt. Ltd. combo dryers are very useful for small print runs on hand tables to high speed production presses. Fast drying possible through unique specially designed air handling system. A separate duct is provided to remove solvent laden air. The opening duct is easily adjustable depending upon the solvent content of the ink being dried. Air is forced at high pressure through heating element into the drying hood and then through air curtains on hood. The twin blower cooling system is designed to take only fresh air for optimum drying efficiency.

- Curing UV intensity selectable 300 Watts/Inch or 200 Watts/Inch

- Conveyor belt speed adjustable

- Independent air circulation for irradiator cooling & hold down cum hot air exhaust

- Unique Ellipticle design of irradiator

- Silver coated reflector for Long Life and better reflection

- Efficient air cooling system for Long Life of curing tube

High-Speed Automatic Curing

This curing machine is designed for automatic, high-throughput operations, capable of curing up to 45 meters per minute. Its advanced mechanism increases productivity in industrial printing or coating lines, making it ideal for businesses dealing with large volumes and requiring consistent, efficient results.

Precision Engineering and PLC Control

Equipped with a Siemens-powered PLC control system, the unit guarantees enhanced accuracy and straightforward computerized operation. It offers easy parameter adjustments and stable performance, ensuring seamless management of curing intensity and timing for various UV-curable inks.

Sturdy Build and Versatile Sizing

The curing machine features a solid build with a curing width of 16 inches, which suits a variety of substrates and formats. Its robust construction (dimensions: 110 x 38 x 57 inches) ensures durability and stability for continuous operation, catering to the demands of industrial environments in India.

FAQs of UV IR Combo Curing Unit:

Q: How does the UV IR Combo Curing Unit operate automatically?

A: The curing unit uses a computerized PLC control system and automatic grade features to streamline the curing process. Once configured, it manages ink curing speed, intensity, and conveyor movement, allowing for autonomous, consistent operation without manual intervention.Q: What types of inks can this curing machine handle?

A: This unit is optimized for UV Curing Inks, making it suitable for modern printing and coating industries that utilize UV-curable formulations. The combination of UV and IR technology broadens application versatility and ensures rapid, uniform ink curing.Q: When is it ideal to use this curing machine in production?

A: It is most beneficial when consistent, high-speed curing is required, such as in high-volume print runs or continuous production lines. Its speed capacity of 45 meters per minute allows for seamless integration where efficiency and uniformity are critical.Q: Where is the UV IR Combo Curing Unit typically installed?

A: This machine is ideally installed in industrial or commercial printing facilities, manufacturing plants, or any environment that requires reliable curing of UV inks. Its robust dimensions and design make it suitable for heavy-duty usage in Indian manufacturing settings.Q: What is the process for controlling curing settings?

A: All operational parametersincluding speed, intensity, and timingare managed through the built-in Siemens PLC control system. Operators use the computerized interface to set and modify curing parameters, ensuring optimal results for different ink and substrate types.Q: How does the curing machine benefit manufacturers and exporters?

A: With its automatic functions, high-speed capacity, and precise controls, the unit optimizes production efficiency, reduces downtime, and enhances product quality. The one-year warranty offers additional peace of mind for manufacturers, exporters, and suppliers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Post Press Machine Category

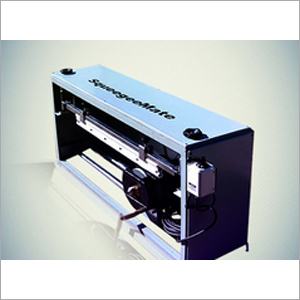

Automatic Squeegee Sharpener

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 115120 Volt (v)

Automatic Grade : Automatic

Computerized : No

Size : 80

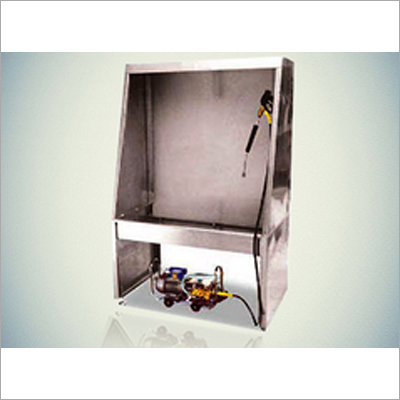

Washing Tank with Back Light

Price 375000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 230 VAC Volt (v)

Automatic Grade : Manual

Computerized : No

Size : 30

Uv Curing Dryer

Price 370000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 430 VAC Volt (v)

Automatic Grade : Automatic

Computerized : Yes

Size : 16

Infra Red Curing Machine

Price 550000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 380 Volt (v)

Automatic Grade : Automatic

Computerized : Yes

Size : 16

Send Inquiry

Send Inquiry