Welcome to Our Company

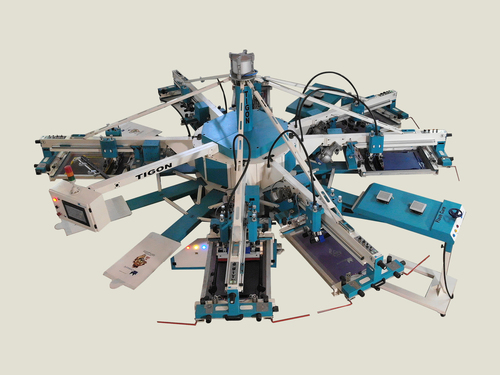

Textile Screen Printing Machine

2500000 INR/Unit

Product Details:

- Type Textile Screen Printing Machine

- Material Steel

- Computerized No

- Automatic Grade Semi-Automatic

- Size Sizes Available

- Warranty One Year

- Click to view more

X

Textile Screen Printing Machine Price And Quantity

- 1 Unit

- 2500000 INR/Unit

Textile Screen Printing Machine Product Specifications

- Sizes Available

- Steel

- One Year

- No

- Textile Screen Printing Machine

- Semi-Automatic

Textile Screen Printing Machine Trade Information

- 10 Unit Per Month

- 7 Days

- Dadra and Nagar Haveli Himachal Pradesh Andaman and Nicobar Islands Uttarakhand Daman and Diu Lakshadweep Nagaland South India North India East India Andhra Pradesh Assam Arunachal Pradesh Bihar Chandigarh Delhi Gujarat Goa Haryana Jammu and Kashmir Jharkhand Karnataka Kerala Madhya Pradesh Maharashtra Mizoram Meghalaya Manipur Punjab Pondicherry Rajasthan Sikkim Tamil Nadu Telangana Tripura Uttar Pradesh West Bengal Odisha Central India West India Chhattisgarh All India

Product Description

The offered Pneumatic Textile Screen Printing Machine is offered by us that is suitable for use in the various commercial and industrial applications. In screen printing a fine mesh screen made of polyester, nylon, or sometimes metal is stretched over a flat wooden frame, that looks a lot like a picture frame. Printing is the prints on fabric with a combination of design and color. Printing is the process of painting a design drawn by an artist and fixation to the fabric or materials with a mixture of different chemicals and dyes. Pneumatic Textile Screen Printing Machine is very efficient and useful.

Frequently Asked Questions:

1) What is a textile screen printing machine?

A textile screen printing machine is a machine that is used to print designs or patterns onto fabric.

2) How does a textile screen printing machine work?

A textile screen printing machine is a machine that is used to print designs or patterns on textile fabrics. The machine consists of a frame, a screen, and a squeegee. The frame holds the screen in place while the squeegee is used to push the ink through the screen onto the fabric

3) What are the benefits of using a textile screen printing machine?

There are many benefits of using a textile screen printing machine, including the ability to print on a variety of different materials, the ability to print in a variety of different colors, and the ability to print in a variety of different sizes.

4) How can I ensure that my textile screen printing machine is running smoothly?

There are a few things you can do to ensure that your textile screen printing machine is running smoothly. First, make sure that the screen is properly tensioned. Second, make sure that the screen is properly aligned. Third, make sure that the squeegee is properly tensioned.

5) What are some of the most common problems that can occur with textile screen printing machines?

Some of the most common problems that can occur with textile screen printing machines include misaligned screens, improper tension on the screens, and ink buildup on the screens.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free