4-Pillar Screen Printing Machine

Price 780000.00 INR/ Unit

4-Pillar Screen Printing Machine Specification

- Capacity

- 1800-2000 Pcs/Hour Kg/hr

- Printing Speed

- 1800-2000 Pcs/Hour mm/m

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Print Direction

- Uni-Directional

- Ink Type

- Other

- Power

- 230 Volt (v)

- Size

- FP-2436

- Width

- 1397 Millimeter (mm)

- Dimension (L*W*H)

- 2133.6 Millimeter (mm)

- Warranty

- One Year

4-Pillar Screen Printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- Week

- Packaging Details

- wooden packing

- Main Domestic Market

- Himachal Pradesh, Pondicherry, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Mizoram, Punjab, Telangana, Haryana, Goa, Tripura, Meghalaya, Arunachal Pradesh, Jammu and Kashmir, Andhra Pradesh, Karnataka, South India, East India, Rajasthan, North India, Tamil Nadu, Manipur, Chandigarh, Jharkhand, Assam, Bihar, Maharashtra, Madhya Pradesh, Sikkim, West Bengal, Andaman and Nicobar Islands, Delhi, Gujarat, Uttar Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

About 4-Pillar Screen Printing Machine

Umrao Automation Pvt. Ltd. introduces the fines and trouble freesemiautomatic flatbed Screen printing Machine. Four Pillars is easy to setup,easy to control, heavy duty and durable construction gives maximum stability atfull production speed with top quality prints and with accuracy required forhigh quality screen printing.

Squeegeehead on solid steel shafts with linear bearing motion to give accurate andvibration free squeegee movement is designed with outstanding features yourbenefits.

Applications:Flat surface printing on Ceramic Tiles Transfers, Printed Circuit Boards,Textile Transfers, Paper, Stickers, Metal Labels, Membrane switch Printing,Commercial Screen Printing etc.

Speed and Precision in Every Print

Experience efficiency with the 4-Pillar Screen Printing Machine, designed to deliver high-speed output of up to 2000 pieces per hour. Its computerized, uni-directional printing ensures accuracy and consistency, making it a dependable asset for mass production printing tasks. The FP-2436s robust build and advanced controls provide both durability and quality for demanding environments.

Optimized for Modern Production Needs

With semi-automatic operation, the FP-2436 streamlines the printing process, reducing manual workload and minimizing errors. It supports a wide array of printing materials and is ideal for use in commercial, industrial, and export-oriented applications. The machines compact dimensions allow for easy integration into existing facilities without compromising production space.

FAQs of 4-Pillar Screen Printing Machine:

Q: How can I operate the 4-Pillar Screen Printing Machine efficiently?

A: To operate this machine efficiently, follow the computerized controls for setup, load the material, and monitor the semi-automatic printing process. The uni-directional print feature ensures consistent results, minimizing the need for manual adjustments.Q: What print capacity and speed does the FP-2436 model offer?

A: The FP-2436 4-Pillar Screen Printing Machine has a print capacity and speed of 1800-2000 pieces per hour, making it suitable for businesses with high-volume printing requirements.Q: When should regular maintenance be performed to ensure optimal performance?

A: Regular maintenance, such as cleaning the screens, checking for wear in movable parts, and verifying the computerized system, should be performed monthly or as recommended in the user manual. This helps sustain printing quality and extends machine lifespan.Q: Where is the 4-Pillar Screen Printing Machine manufactured and supplied?

A: This machine is manufactured, exported, and supplied from India, catering to clients across the country and internationally, depending on the suppliers distribution network.Q: What is the process for installing the FP-2436 Screen Printing Machine?

A: Installation involves positioning the machine in your facility, connecting it to a 230-volt power supply, calibrating the computerized control system, and performing initial test prints to ensure everything is set correctly.Q: What are the key benefits of using this semi-automatic screen printing machine?

A: The main benefits include high-speed output, reduced manual intervention due to semi-automation, precise uni-directional printing, and a one-year warranty, offering both productivity and peace of mind for business owners.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Printing Press Machine Category

Roll To Roll Screen Printing Machine

Price 1950000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Size : Standard, Customizable

Printing Speed : 2000 Impressions/hr mm/m

Textile Curing Machine

Price 370000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Automatic Grade : SemiAutomatic

Computerized : No

Size : 25

Printing Speed : 500800 pcs/hour PPM

Roll To Roll Printing Machine

Price 2200000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Size : 20" x 30"

Printing Speed : 18002000 Pcs/Hour mm/m

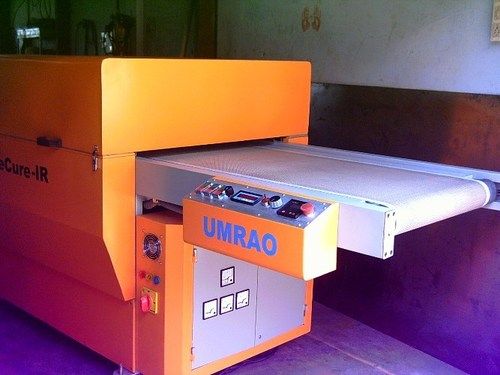

Infrared Curing Machine

Price 470000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Size : 25

Printing Speed : 220 mm/m

Send Inquiry

Send Inquiry